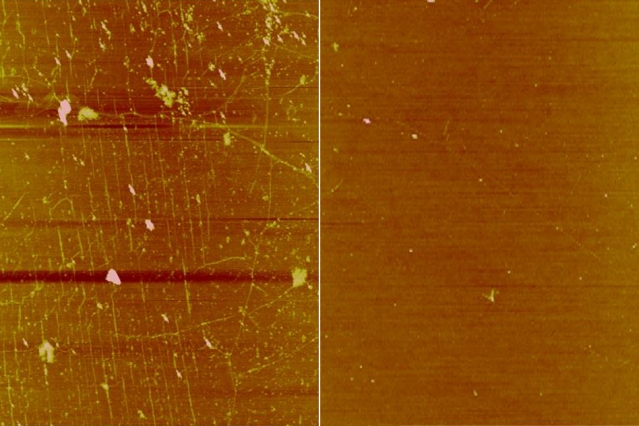

Navson Spin Coaters find use in many scientific labs, research institutes and industrial processes. Like in the deposition of ultrathin polymer films and semiconductor device fabrication. The spin coating method is also extensively used in photolithography for photoresist layers of about 1 micrometer thick. Recently, researchers at MIT have used spin coater to put layers of wax to protect the atom-thin material, Graphene, from performance-impairing wrinkles and contaminants that mar its surface during device fabrication.

Used Spin Coater for Smoothing Wrinkles in Graphene

- Graphene, a fragile material

- Challenge, while transferring to new substrate

- Traditional method introduces defects and impairs performance

- Spin coating paraffin and layering it on graphene introduces a protective layer

- Paraffin layer when heated, expands and removes wrinkles in graphene layer

Courtesy of the researchers